Plastic woven pearlescent film color bags

Product planning and design

Consult now

Product planning and design

Consult now

The outer layer: The BOPP film layer serves as the outermost layer, providing an excellent printing surface that enables clear and vivid pattern or text printing, enhancing the aesthetic appeal and brand recognition of the packaging.

Middle layer: The pearlescent film layer endows the packaging with a unique pearlescent luster, which can enhance the product's grade and visual appeal, assist in improving the overall structural stiffness, and make the bag more stylish.

The inner layer: The plastic woven fabric layer provides a support base for the BOPP film and pearlescent film, ensuring the stability of the overall structure.

The outer layer: The BOPP film layer serves as the outermost layer, providing an excellent printing surface that enables clear and vivid pattern or text printing, enhancing the aesthetic appeal and brand recognition of the packaging.

Middle layer: The pearlescent film layer endows the packaging with a unique pearlescent luster, which can enhance the product's grade and visual appeal, assist in improving the overall structural stiffness, and make the bag more stylish.

The inner layer: The plastic woven fabric layer provides a support base for the BOPP film and pearlescent film, ensuring the stability of the overall structure.

1. Food packaging: It is suitable for packaging rice, flour, coarse grains, sugar, nuts and other foods. It can not only protect the food from moisture and contamination, but also enhance the market competitiveness of the product through exquisite packaging.

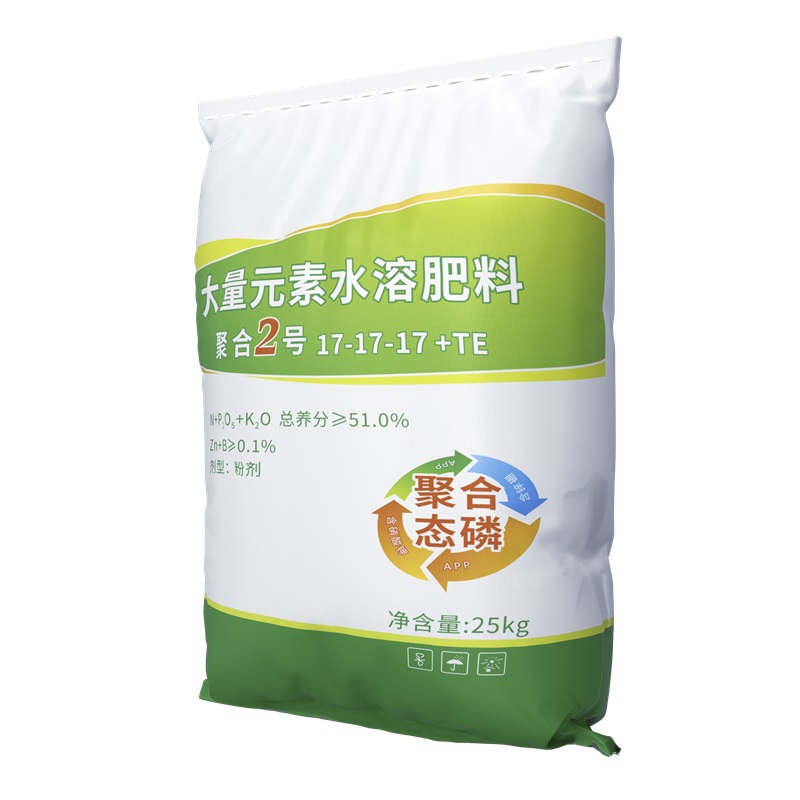

2. Agricultural supplies packaging: It can be used to package agricultural supplies such as fertilizers, pesticides, and seeds. Its excellent barrier properties and strength can ensure the quality and safety of the products during storage and transportation. Meanwhile, color printing can serve as publicity and identification, facilitating farmers' recognition and use.

3. Chemical product packaging: For various powdered and granular chemical raw materials, such as plastic particles, coatings, pigments, detergents, etc., plastic woven pearlescent film color bags can provide effective packaging protection, preventing product leakage and moisture deterioration.

4. Other fields: It can also be applied to the packaging of building material powders, mineral powders, feed, pet food and other products, as well as used as shopping bags, gift bags, etc., meeting the packaging needs of different industries and scenarios.

1. Food packaging: It is suitable for packaging rice, flour, coarse grains, sugar, nuts and other foods. It can not only protect the food from moisture and contamination, but also enhance the market competitiveness of the product through exquisite packaging.

2. Agricultural supplies packaging: It can be used to package agricultural supplies such as fertilizers, pesticides, and seeds. Its excellent barrier properties and strength can ensure the quality and safety of the products during storage and transportation. Meanwhile, color printing can serve as publicity and identification, facilitating farmers' recognition and use.

3. Chemical product packaging: For various powdered and granular chemical raw materials, such as plastic particles, coatings, pigments, detergents, etc., plastic woven pearlescent film color bags can provide effective packaging protection, preventing product leakage and moisture deterioration.

4. Other fields: It can also be applied to the packaging of building material powders, mineral powders, feed, pet food and other products, as well as used as shopping bags, gift bags, etc., meeting the packaging needs of different industries and scenarios.

The PP resin is heated and melted through an extruder, and then extruded through a flat die head to form a uniformly thick molten film "coating layer", which is then covered on the surface of the substrate to be laminated. Then, with the pressure of the pressure roller, the pearlescent film is bonded to the molten lamination layer. After cooling and solidification, a five-layer structure of "BOPP film - lamination layer - pearlescent film - lamination layer - woven fabric" is finally formed.

The PP resin is heated and melted through an extruder, and then extruded through a flat die head to form a uniformly thick molten film "coating layer", which is then covered on the surface of the substrate to be laminated. Then, with the pressure of the pressure roller, the pearlescent film is bonded to the molten lamination layer. After cooling and solidification, a five-layer structure of "BOPP film - lamination layer - pearlescent film - lamination layer - woven fabric" is finally formed.