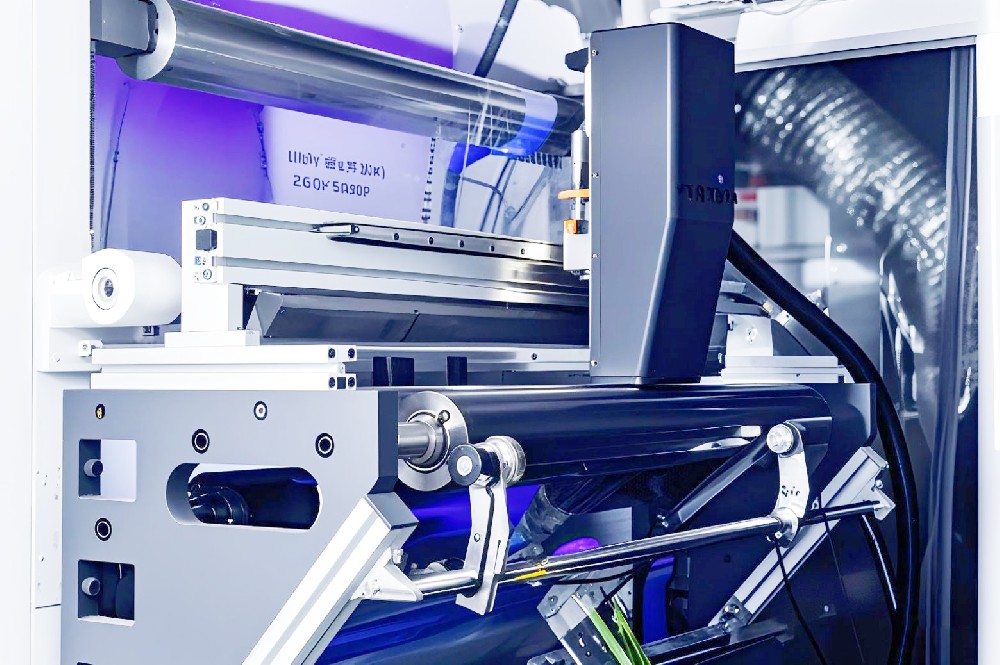

Wire drawing process

Formulate the corresponding process formula in accordance with the standard requirements, and produce qualified threads under the set process conditions such as process temperature and stretch ratio.

About Us

Shifang Liansheng Packaging is a one-stop, customized global supplier of plastic woven packaging. The company's customer base has covered more than ten different industries, including the Petrochemical industry, the Chemical industry, the Feed industry, the Food industry, the Fertilizer industry, the Mining industry, the Building industry, and the New Energy industry. The type of products contain multiple categories, such as plastic-woven pearlescent film color bags, plastic-woven non-woven fabric color bags, plastic-woven ordinary double-color bags, plastic-woven single-color bags, plastic-woven printed bags, plastic-woven laminated bags, plastic-woven handbags, ordinary container bag, static protection container bag, temperature-resistant container bag, ultraviolet-resistant container bag, stretching bag, soft pallets, etc.

The company has fixed assets of 200 million yuan, a modern production base of 30,000 square meters, and over 500 sets of advanced production equipment, together with more than 300 experienced and skilled production technicians. The annual production capacity of various types of woven bags is 100 million pieces, and medium and high-end flexible container bags is more than 1 million pieces.

Since establishment, the company has always adhered to the development concept of "seeking development through innovation and survival through quality", striving to provide customers with high-quality products and excellent services, and actively contributing to the development of the packaging industry.

2005years

The company was established in20000Ten thousand yuan

The total investment exceeds300+people

The current employees of the company30000Square meters

The company's land areaProducts and services

Capacity

Formulate the corresponding process formula in accordance with the standard requirements, and produce qualified threads under the set process conditions such as process temperature and stretch ratio.

Use qualified threads to weave the base fabric with a width that meets the requirements of the woven bag standards.

Layout, color matching and printing are carried out in accordance with the patterns required by the woven bag production standards to produce qualified color films and fabric rolls.

According to the requirements for the production of woven bags, automatic sewing, film covering and sealing should be carried out. Thread skipping, thread breaking and thread end not locking are not allowed

The produced woven bags are packaged and bundled. They are bundled in the quantity required by the customer, and proper labeling and stacking are carried out.

Through finished product processing, quality control and packaging and warehousing, container bags are transformed from semi-finished products into qualified finished products, ultimately meeting customers' demands for product quality, appearance and functional use.

News Center

Cooperative partner