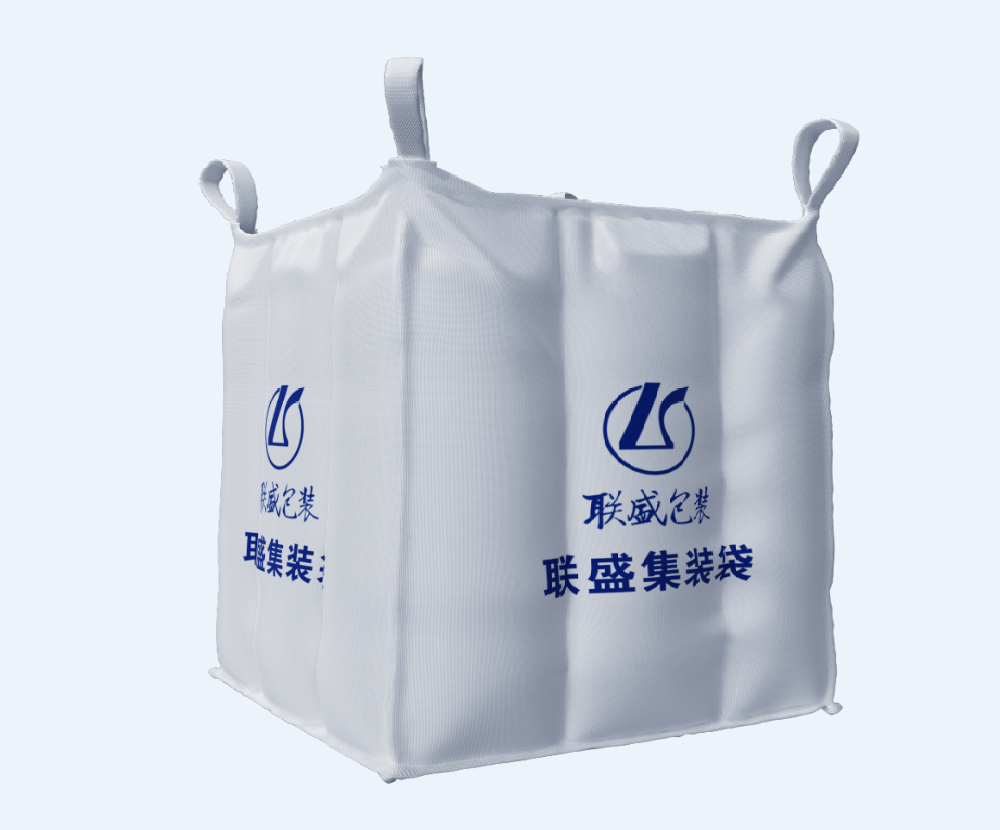

Square bulk bag

Product planning and design

Consult now

Product planning and design

Consult now

Regular shape: It has four sides and two bottom surfaces at the top and bottom, presenting a rectangular or cubic shape. This can better utilize storage and transportation space, facilitate stacking and placement, and has good stability.

Balanced force distribution: There are usually four lifting rings at the top, which can be loaded, unloaded and transported by equipment such as cranes or forklifts. The weight of the goods can be evenly distributed to the four lifting points, making the hoisting process safer and more stable.

Sealability: Usually, the top is equipped with openings that can be opened and closed, facilitating the loading and unloading of goods. After loading the goods, the openings can be closed to protect the goods. Some square bulk bags may also have discharge ports at the bottom for easy unloading.

Chemical industry: It is used for packaging various powder, granular and block chemical raw materials and products, such as fertilizers, plastic pellets, soda ash, caustic soda, etc.

Construction industry: It can load building materials such as cement, sand, gravel, gypsum powder, and putty powder, facilitating transportation and use on construction sites.

Food industry: It is often used for packaging rice, flour, beans, sugar, salt and other foods, which can effectively protect food from moisture and contamination, ensuring the quality and safety of food.

Mining industry: It can be used to load mineral products such as ores and mineral powders, facilitating the transportation and storage of mineral resources.

Other fields: It is also widely used in agriculture, logistics, warehousing and other fields, such as packaging feed, seeds, industrial salt, etc., and can also be used as a temporary storage container for large goods.

The main material is generally made of flat filaments woven from high molecular materials such as polypropylene (PP) or polyethylene (PE), featuring high strength, good toughness, corrosion resistance and moisture resistance.

Auxiliary materials: Slings are usually made of high-strength polyester fibers or nylon and other materials to ensure they can withstand the weight of the container bag when fully loaded. To enhance the waterproof and moisture-proof performance of container bags, a layer of plastic film or other materials may be coated or compounded on the surface of the woven fabric.

The main material is generally made of flat filaments woven from high molecular materials such as polypropylene (PP) or polyethylene (PE), featuring high strength, good toughness, corrosion resistance and moisture resistance.

Auxiliary materials: Slings are usually made of high-strength polyester fibers or nylon and other materials to ensure they can withstand the weight of the container bag when fully loaded. To enhance the waterproof and moisture-proof performance of container bags, a layer of plastic film or other materials may be coated or compounded on the surface of the woven fabric.