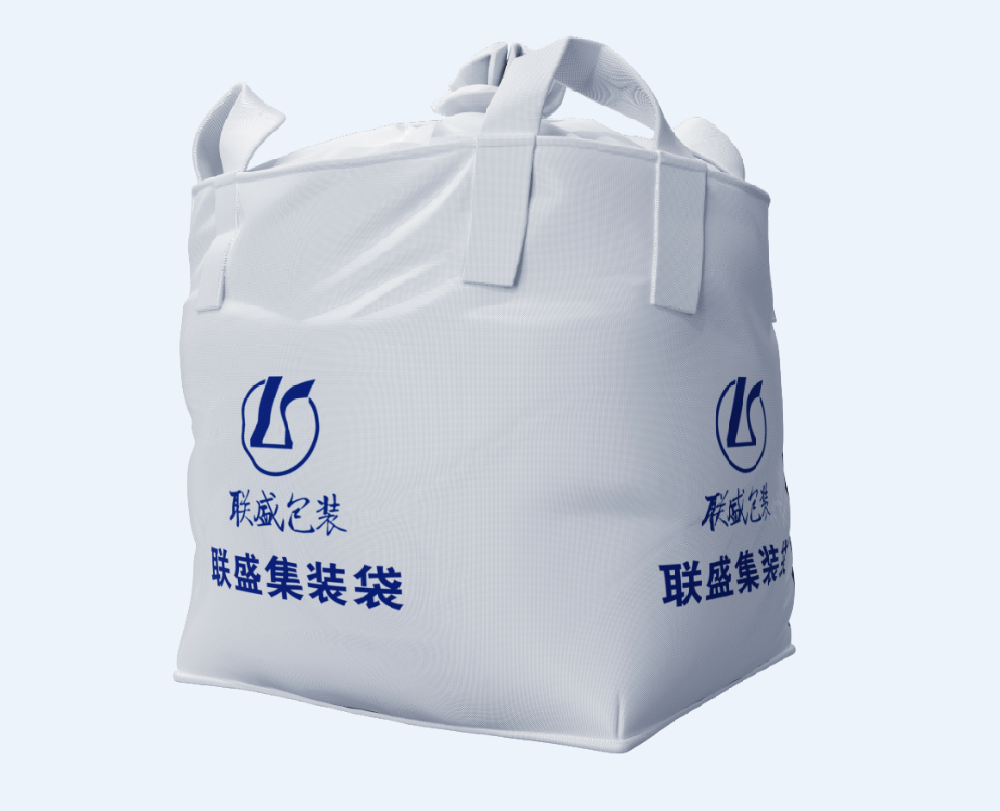

U-shaped bulk bag

Product planning and design

Consult now

Product planning and design

Consult now

Unique shape: Composed of two arched bag bodies connected at the bottom and top, it forms a structure similar to a tunnel.

The lifting structures are diverse: there are different forms such as top lifting type, side lifting type and bottom lifting type.

Flexible opening Settings: Usually, there are inlet and outlet ports, which facilitate the loading and unloading of materials. According to actual needs, openings of different forms and sizes can be set at the top, bottom or side.

Chemical industry: It is used for packaging various powdered and granular chemical raw materials and products, such as fertilizers, plastic pellets, soda ash, etc.

Construction industry: It can load building materials such as cement, sand and gypsum powder.

Food industry: It is often used for packaging rice, flour, beans and other foods.

Mining industry: Suitable for loading mineral products such as ores and mineral powders.

The main material: Generally, polypropylene (PP) or polyethylene (PE) is used as the main raw material. It is processed through extrusion to form a film, cutting, drawing, and then woven into woven fabric. This woven fabric features high strength, good toughness, corrosion resistance and moisture resistance.

Auxiliary materials: The lifting slings are made of high-strength polyester fibers or nylon and other materials to ensure they can bear the weight of the fully loaded container bags. Sometimes, to enhance the waterproof and moisture-proof performance, a layer of plastic film or other materials is coated or compounded on the surface of the woven fabric.

The main material: Generally, polypropylene (PP) or polyethylene (PE) is used as the main raw material. It is processed through extrusion to form a film, cutting, drawing, and then woven into woven fabric. This woven fabric features high strength, good toughness, corrosion resistance and moisture resistance.

Auxiliary materials: The lifting slings are made of high-strength polyester fibers or nylon and other materials to ensure they can bear the weight of the fully loaded container bags. Sometimes, to enhance the waterproof and moisture-proof performance, a layer of plastic film or other materials is coated or compounded on the surface of the woven fabric.